Many of the air compressors on the market today are priced very well. The main problem with these “value” types of air compressors is that they are all usually lacking in one department.

The sound department. Yes. Almost all of the air compressors that are well-priced tend to be very loud. It seems to me that a decreased price tag on an air compressor usually leads to a louder machine.

If having a loud and noisy air compressor is something you are trying to fix, then I may have a solution that will work for you.

I have done a lot of research on how to make an air compressor quieter and found quite a few different and unique ways to do this.

Before we get into how to make them quieter, let’s first take a look at what makes an air compressor loud, to begin with.

How Loud Is an Air Compressor, to Begin With?

You can use a decibel meter like this one from amazon to find out exactly how loud your air compressor really is. A decibel meter is a tool that places a number on an item called a decibel.

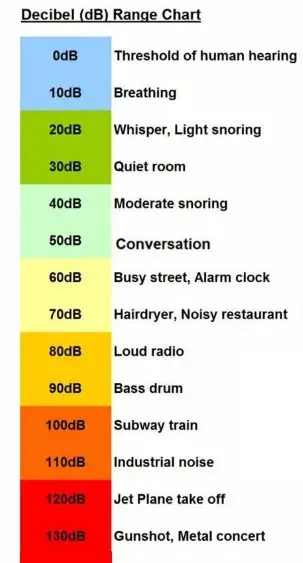

A decibel is a measure of sound heard by the human ear. In order to understand a decibel meter, you will need to compare your reading to a chart.

I have provided a chart for you down below so you can potentially see how loud your air compressor is compared to other real-world scenarios.

Generally speaking, an air compressor with a dB higher than 80 is usually considered loud. Anything under about 75 dB can be considered quiet.

The average compressor seems to put on about 70 to 90 dB, but the majority of compressors on the market will stick to around 80 to 85 dB if they are not specifically made to be quiet.

As you can see from the chart below, this is still quite loud.

It’s important to use some form of decibel meter so you can assess how loud your compressor currently is to actually see if your efforts are indeed fact making your air compressor quieter.

What Makes an Air Compressor Noisy?

There are numerous factors that can contribute to how loud an air compressor is.

Some noises are caused by vibrations, while others are more related to intake and exhaust noises.

It’s safe to say that all these noises going off at the same time works against having a quiet air compressor.

Some of the main things that contribute to how loud your compressor is are:

Exhaust: The exhaust is one of the major components that contributes to how loud it is.

This is usually geared towards a compressor with a gasoline engine mounted to it. The exhaust lets out all the byproducts from your machine.

Intake: The intake portion of an air compressor is probably one of the loudest components.

An intake simply sucks air into the compressor in order for it to work properly.

Vibration: Vibrations play a smaller role in the amount of noise generated from a compressor but is annoying nonetheless.

Vibration usually depends on the structural integrity of the air compressor you are using. If there are a lot of loose or hollow parts, the vibration noise will be much more prominent.

The material the Air Compressor Is Made Of: The material the compressor is made of will also affect how it will sound while it is running.

A more expensive compressor will be made up of a higher-grade metal and is usually thick and dense. The denser a material is, the more sound-absorbing properties it can provide.

What You Place Your Air Compressor On: The floor or ground that you place your air compressor on plays a big role.

Hardwood flooring and concrete tend to make your compressor louder solely due to the echoes and reverberations they will cause. The best case scenario is to use a thick rubber mat or soft ground to place your compressor on.

The Type of Air Compressor You Have: If you have a super cheap air compressor, then you better expect it to be loud.

More expensive ones tend to be on the quieter side, but don’t just look at the price tag to determine that. Not all expensive compressors are quiet so you will have to keep this in mind as well.

Generally speaking, stronger air compressors tend to be a lot louder than smaller quiet models.

Some companies actually specialize in quiet air compressors and will proudly display that in their product title or description.

How Can You Make an Air Compressor Quieter?

Now that you understand the components that make a compressor noisy, it’s time to see what you can do to make them quieter.

Quite a few of these methods are DIY (do it yourself) since there aren’t really any products on the market specifically designed to reduce noise from these machines.

Making an air compressor quiet is a lot similar to reducing noise in a portable generator.

- Modifying the intake and exhaust system on a compressor is one way to help reduce noise.

- Adding thick rubber to various portions of a compressor can help with vibration noises. Most of the vibration will be coming strictly from the compressor’s motor.

- The ground or platform your compressor rests on is a big factor in how loud the vibration noises will be. It’s always best to place your compressor on some sort of thick rubber mat or soft ground. Try not to run your air compressor on hard concrete or wood flooring as this will increase reverberations and echos from the vibrations.

- If all else fails, then you can upgrade to an air compressor specifically designed to be quieter than the standard ones on the market.

Install Rubber Grommets on the Motor

Rubber is an excellent material to use when trying to soundproof something. Using a dense piece of rubber is very effective at absorbing impact noise and shock.

The reason rubber works so well is because it acts as a dampener. A sound dampener is something that absorbs energy instead of letting it echo or pass through.

Install rubber grommets on the motor mounting bracket on the frame itself, which will help eliminate the vibration noise when the compressor is powered on.

This rubber grommet assortment set from amazon is a good choice since it is cheap and comes in many different sizes.

You can use the extra grommets for other projects you have to lie around.

Now, this method will not work with every air compressor, but if you have a model similar to the one it was used on, then you can definitely do this to yours.

Here is a video I found showing how to install the rubber grommets onto the frame.

Extend the Intake to the Outside

Another method you can try is to extend your compressor’s intake to somewhere outside. Most air compressors are used inside of a garage which can cause a lot of noise from echoing.

A cool little trick is to make the intake pull air from the outside of your garage to eliminate the loud sucking noises.

This sounds more difficult to do than it really is. It also requires very few materials to get working.

All you need is a rubber hose that is big enough to fit over the intake of the compressor and a bracket. The bracket is used to fasten the hose to the intake.

Push the rubber hose snugly onto your compressor’s intake. Apply the bracket to make sure it stays nice and snug. You will then need to either use an existing hole or cut one out of the wall.

This hole should be outside. You can then create a small enclosure around the exposed hose with sheet metal to further reduce noise.

Here is a video showing what your air compressor should look like when it’s up and running.

Connect a Muffler to the Intake

This is another great DIY method to reduce the dB of your air compressor. This method uses heavy-duty air hoses.

The air hoses are connected to the intake of the compressor and then to a muffler, and then back out onto another air hose.

This method does require some work and a muffler. Not everybody has a muffler lying around their garage, so the practicality of this method may be low, but it is unique and effective nonetheless.

The user who performed this method reported a decrease of 4 dB from his air compressor.

4 dB may not sound like a lot, but it can actually be the difference between a loud or quiet compressor based on where it currently stands on the dB chart.

Here is the video I found showing you how to connect the intake to a muffler.

Consider Purchasing a Quiet Air Compressor

Many of the methods shown above are mostly do-it-yourself projects that don’t really solve the problem.

Sure placing the intake on the outside of your garage will quiet it a few decibels, but is it practical? A lot of these different methods to quiet down an air compressor are not really practical.

If you have a portable air compressor, then you can’t perform many of these things to quiet it down.

I can’t see myself bringing my air compressor with me with a muffler attached to it. That’s just insane. I would rather save up for an affordable air compressor that isn’t as loud.

The best thing to do if you are sick and tired of having an ultra-loud compressor is to purchase a new one, hands down. Not just any air compressor. One that is specifically designed with being quiet in mind.

This ultra-quiet air compressor on amazon is an incredible 60 dB! If you look at 60 dB on the chart I provided up above; this is equivalent to an alarm clock.

Not only is it super quiet, but it’s super affordable. There is no need to spend $500 on an air compressor for it to be quiet. Technology has evolved a lot over time and has allowed us to have these things at lower prices.

Comparison Between Belt, Direct Drive, and a Silent Air Compressor

Air compressors are not all created equal. That being said, there are belt-driven, direct drive, and small portable air compressors.

As you can imagine, the direct drive and belt drive will be much louder than a smaller portable compressor. Sometimes close to half as loud, which is incredible.

A direct drive compressor will be the loudest of the bunch. Next up would be the belt driven. The main difference between a belt-driven and direct drive compressor is that the belt-driven ones run at a slower rpm.

Rpm is rotations per minute which is similar to a car. The higher the rpm, the higher the noise.

Although the nonsilent air compressors are a lot more powerful than quiet portable generators, they are also super loud at about 73 to 74dB.

The quiet air compressor used in the test was actually only 40 dB. That is even quieter than the compressor that I recommended above.

When getting to super low dB levels, you must consider how strong you need your air compressor to be. When going quiet, you will be sacrificing some form of power. You will need to figure out the balance that is good for your specific needs.

Here is a video showing the difference between the three air compressors.

Final Thoughts

There is no arguing that air compressors are generally too loud. There are many small modifications that you can do to help reduce the sound somewhat, but all are just temporary fixes for a stationary machine.

If your compressor will stay in your garage at all times, then it wouldn’t be a bad idea to do some of these modifications.

If portability is what you are after, then finding a quiet portable air compressor is your best option. Just remember that with decreased sound comes decreased performance.

Take a look at what you are using your air compressor for. Make sure that your new compressor has the required specs before purchasing.